Why The SDCA Cycle Is Needed Before PDCA?

In the journey of continual improvement, we utilize various ways to improve our manufacturing or administrative sections. We also use various tools for improvement in our industries. In this, PDCA is a quiet popular methodology in the journey of continual improvement and most of the industries utilize this cycle. The PDCA and SDCA both the cycles generally work simultaneously but most people don’t know the importance of the SDCA cycle in the program of the PDCA cycle. If you don’t know the importance of the SDCA cycle then your time, efforts to create continual improvement can be considered as a waste.

Hence if you want to do improvement in your organization then you have to follow the SDCA cycle simultaneously with the PDCA cycle. So in this article, we will discuss the importance of the SDCA cycle. The ISO standard also follows the principles of the PDCA cycle. The organization must apply for the ISO Certification in Delhi to improve the processes in the organization.

Introduction to PDCA and SDCA cycle:-

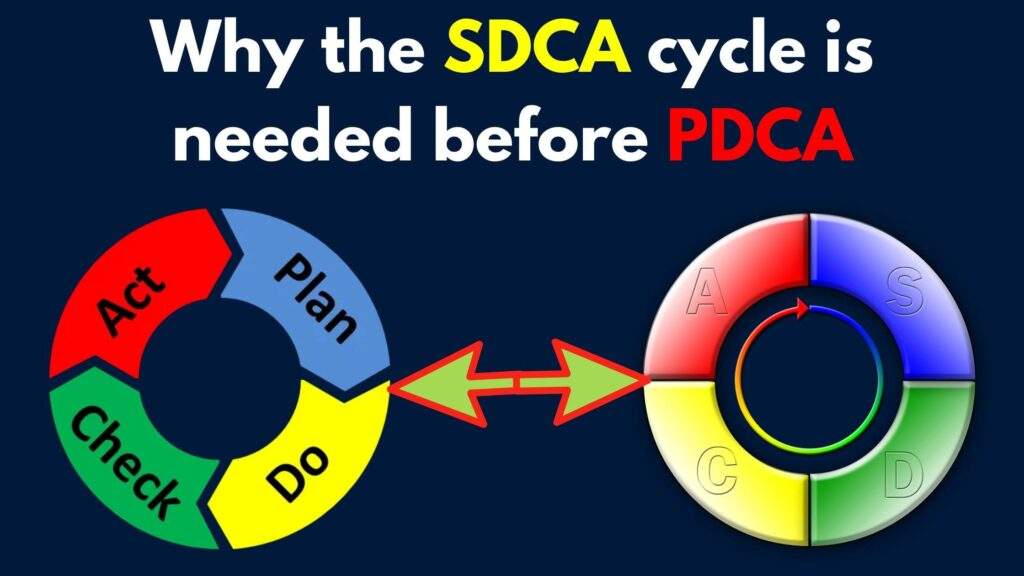

The PDCA is one of the popular methodologies which is used for problem-solving, continual improvement, and project management. And we all know that the PDCA stands for Plan, Do, Check, and Act.

On the other hand, SDCA stands for Standardize, Do, Check and Act.

Importance of SDCA cycle:-

In industry, if we are working on the improvement of any section of the organization such as productivity, and we set a target and improve the processes and enhanced productivity, and we improve it again and again by applying the PDCA methodology. Using the PDCA methodology, we must have identified some root causes and also acted on them. But by working with the PDCA methodology, we had to ensure that we had standardized the processes and the processes do not go in the previous situation.

If we do not standardize and sustain the process that had been improved by us then the previous situation will get reflected in the present and our efforts will be considered as a waste.

Toyota Production System (TPS) is one of the most recognized systems in the world which is used in the manufacturing industries. It was developed by Taiichi Ohno.

According to Taiichi Ohno, if you are doing improvement without any standardization then it can be a waste of efforts.

Without the Standardization of the system, the improvement of the system is impossible.

Hence the SDCA works simultaneously with the PDCA cycle to standardize the processes.

To improve any part of the system, First, the SDCA cycle is used to sustain the processes that are implemented on the system. And after that, the PDCA cycle is implemented for the improvement of the system.

Basically, SDCA helps to ensure that the processes are sustainable. And the PDCA cycle helps to enhance the performance of the system. So it is important for the organization to use the SDCA cycle as well as the PDCA cycle simultaneously.

Conclusion:-

The article explains the relationship between the SDCA and the PDCA cycle. These two cycles are implemented simultaneously or by a sequence to sustain and improve the processes in the organization. These are the important methodologies that are used in the industries to improvise the systems of the organization to get better growth. The Indian organization also follow these cycles in their organization by applying the ISO certification in India.